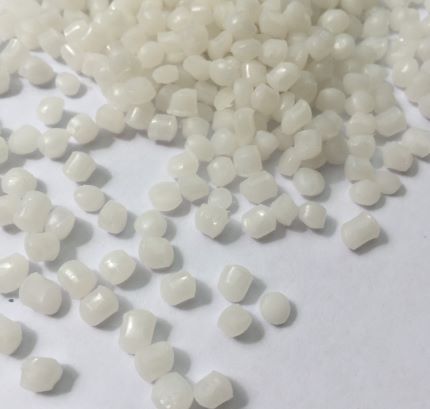

Compound Material

HP-46 Thermoplastic Elastomer

IngredientsHP-46 is High Density Polyethylene、Styrene-Ethylene/Butylene-StyreneblockCopolymer、 Styrene- Butylene-Styrene blockCopolymer、Polyolefin Elastomer、Ethylene-Propylene-Dienes Monomer CompositeElastomer

Physical Properties

| Expansion Ratio | % | 160 ± 2 | 150 ± 2 |

|---|---|---|---|

| Hardness | ASTM D2240 | 45± 3 C | 50± 3 C |

| Specific-Gravity | ASTM D297 | 0.21 ± 0.02 | 0.25 ± 0.02 |

| Tensile Strength | ASTM D412 | 20 MIN | 20 MIN |

| Elongation | ASTM D412 | 300 MIN | 300 MIN |

| Tear Strength | ASTM D624 | 10 MIN | 10 MIN |

| Resilience | ASTM D2632 | 58 MIN | 60 MIN |

| Shrinkage | 70℃ lasting for 40mins | 2 MAX | 2 MAX |

| Compression Set | ASTM D395 B | 45 MAX | 45 MAX |

| Layer Tear | BS 5131 | 2.36 MAX | 2.55 MAX |

Feature

- Instead of Plastic Feeling For EVA Foam to Rubber Touching Once Add HP-56

- ExcellentRebounding AndLow Compression Percentage.

- High Compatibility. It Is Easy To Compound With Rubber、plastic.

- It Is Used On Standard EVA Injection Machine.

- Density Is As Same As EVA.

- Part Dimension Is Stable, Reduce Processing Time AndCost.

- Conform PerformedShoe' Spec.

- It Can Be Used For OutsoleBy Adding Abrasion Agent.

- There Are Two Types Of HP-46: A(78°A) and B(56°A).Mixing Both Of Them In Proportion Confers Excellent Layer Tear Features. Slip Resistant Is Better Than EVA.

Storage

Store In A Place Away From Direct Sunlight And Fire And Heat. The Long-Term Storage Temperature Should Be Less Than 50 °C.

If It Is Not Used After Opening, Please Seal The Inner Bag Of The Package For Easy Storage.